A few updates today as I managed to get quite a bit done before I return to work. The anti-slip texture has been applied to the turret, turret stowage hatches and front fenders and for a first attempt at this I'm quite happy with the result;

Moving onto the hull an easy improvement can be made to the suspension swing arms as there is no detail on the front of them. This involved drilling a 0.80mm pilot hole in the centre to a depth of about 2-3mm, this was enlarged then using a dentists burr the hole was flattened out at the bottom. A short length of 0.75mm styrene rod was then inserted and cut to length, this was then glued into the hole. Doing this makes the featureless kit part look much better and it's an easy fix;

After seeing a Leopard up close I realized just how shallow the rear exhaust grills are on all the kits I have and ordered the welded Leopard Club resin replacements for the C2 (available here;

Leopard club welded exhausts) and the cast ones for the Meng 1A5.

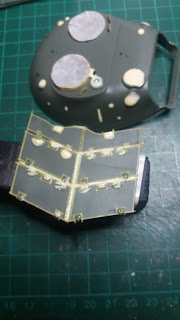

If you do buy these then you need to chop the rear deck before you glue the top and bottom hull parts together. For the Takom kit measure 2mm from the engine grill panel lines and draw a line, then measure 40mm from the top of the side hull, mark it then draw a vertical line down from that. Using a razor saw and feeling brave you then cut out the area that I've shown in the photo;

I chamfered the edges of the kit parts, cleaned them up and the fit of the resin replacements was almost perfect, all they will require is some filling to blend them in afterwards. I must say they look a hell of a lot better;

All the road wheels, idlers and drive sprockets have been cleaned up and glued together, the only other big job will be the track assembly but that will be a separate post. One thing I need to do is put some wear and tear on the tyres as the photos from the Prime Portal website show a fair amount of abuse to them.

So far I'm liking this kit. Some of the details have been simplified particularly the suspension as it's moulded onto the hull whereas these were separate parts on the Revell kit I built in 2016 but generally it's pretty good AND my first ever Takom kit.